AT HOME WITH PICCHIOTTI – BEHIND THE SCENES AT THE ITALIAN HERITAGE BRAND’S ATELIER

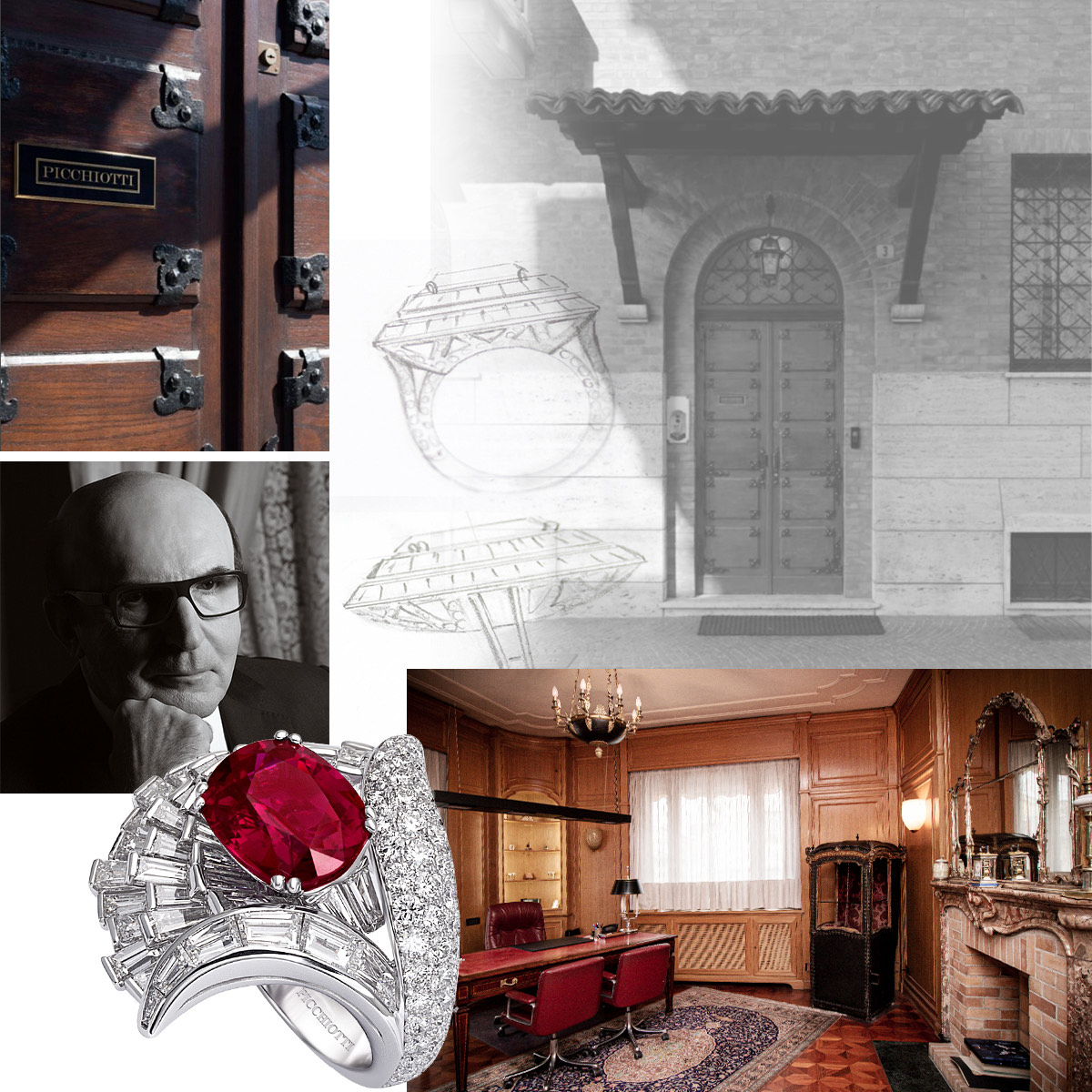

The PICCHIOTTI heritage fine jewelry brand is headquartered in a beautiful building in the heart of Valenza, Italy that dates back to the 1800s. The facility originally belonged to a doctor. Giuseppe Picchiotti, Founder of the PICCHIOTTI brand, bought it from the doctor’s daughter in the late 1970s. After a few years of renovation, the company was relocated to these headquarters (1980) and has remained there ever since. The atelier encompasses all three floors of the building, and each area is articulated with its own specialty – manufacturing on the ground floor (goldsmithing, gemstone setting, polishing), commercial offices on the first floor, and the accounting department on the third floor.

Giuseppe’s office (see feature image above), located on the first floor, is at the heart of the facility in multiple ways. A charming room with walls covered in a fine boiserie, the office is where Giuseppe often does his greatest design thinking and where personal clients and VIPs who visit the atelier are hosted for meetings, jewelry presentations, and afternoon tea in front of the building’s elegant and original Carrara marble fireplace. His desk is an antique table that dates back to the 1800s, near the timing of the building’s construction. It is complete with an antique sedan chair from the 1700s with all of its original parts. The only thing modern about this exemplary office is the addition of LED lights to perfectly showcase the beauty of the jewelry.

“By today’s standard our manufacturing facility may be considered quite small,” says Giuseppe. “Especially as the big brands have come into Valenza and established large manufacturing facilities in recent years. They build factories that can accommodate hundreds of workers, and to me, it somehow removes some of the soul of the craft of the goldsmithing. But the quality, the finesse, and the highly specialized training that can be found in our workshop is unique, and I am proud to say, second to none!”

Design

PICCHIOTTI Masterpieces Peacock Brooch, molds and design sketches for peacock brooch, wax mold and rough cast piece, CAD drawing on the computer, PICCHIOTTI Sapphire and Marquise Diamond Fiocco Bow ring, hand drawn design sketch of the Fiocco ring

As a beloved Italian jewelry brand, known for exquisite classically inspired design, we must dedicate a part of our atelier to the design process itself. Nature and architecture are the primary design inspirations at PICCHIOTTI, and on any given day, three designers can be found working with Giuseppe on the intricate design details of each and every piece we produce. Two of the designers are dedicated purely to design, conceiving of innovative ideas and sketching them; while the other is dedicated to CAD (computer assisted design) projects. The CAD designer works closely with the goldsmiths to ensure the perfection of the pieces, from a manufacturing point of view. Interestingly, every PICCHIOTTI family member is involved in design. New designs often originate from the stones themselves. When Fillipo Picchiotti and his father Giuseppe return from worldwide buying trips or exclusive gemstone partners send first-right-of-refusal goods to PICCHIOTTI, the team will immediately begin to build a design around the superlative gemstones. Other designs stem from architectural or natural beauty, seen all around the atelier in Valenza and throughout Italy. As each new design is conceived and drawn, the entire family votes regarding whether or not to proceed with manufacturing.

Giuseppe himself is a traditionalist, partial to hand-drawn designs. For this reason, the PICCHIOTTI archives contain a vast array of state-of-the-art designs executed with traditional techniques, such as pencil or watercolor. In the modern world, however, much of the jewelry design process is completed with CAD (computer assisted design) and 3-D printers that help to create molds for casting. PICCHIOTTI has always been keen on new technology, and for this reason, the brand has embraced 3-D printing as part of their processes since its early inception.

Goldsmithing

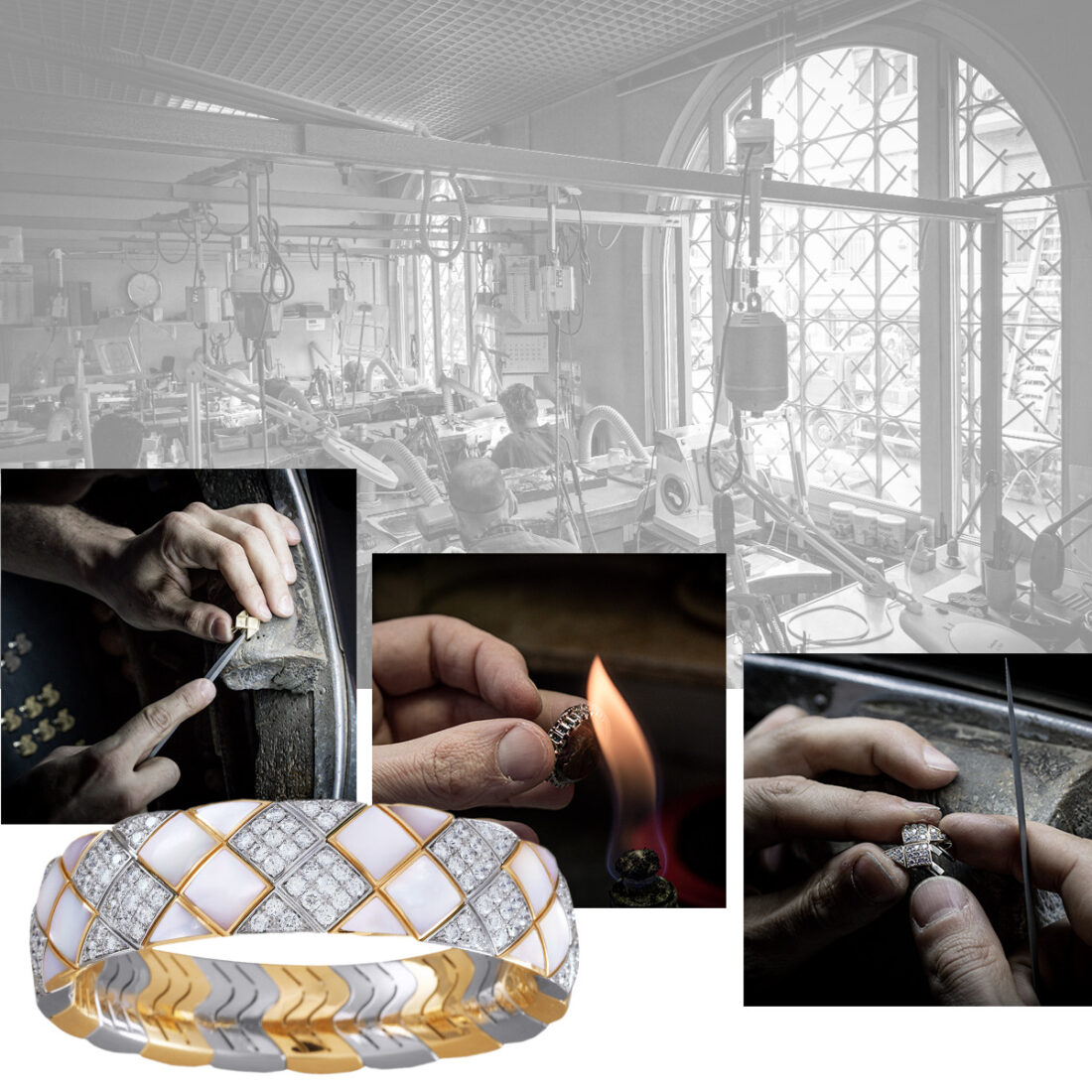

Clockwise from top – PICCHIOTTI atelier Goldsmithing area, goldsmith hand-assembling parts, PICCHIOTTI Xpandable™️ Mother of Pearl and Diamond bracelet, goldsmith filing and perfecting individual parts, flame forging a ring

The main section of the PICCHIOTTI building is dedicated to the goldsmiths. These artisans are the true heroes that bring the new jewelry designs to life. Located on the ground floor, the goldsmithing area of the atelier is home to over a dozen craftsmen who mold the precious metals into the wearable works of art that PICCHIOTTI is famous for.

Highly skilled workers are typically trained in the various ways of shaping precious metal. The artisans use filing, soldering, sawing, forging, casting, and polishing techniques to create the precious metal base for the PICCHIOTTI designs. As you tour the goldsmithing area, you may see a craftsman working with fire to form and shape the molten gold or heat a piece for refined shaping. You might also see carvers working by hand or master goldsmiths filing gold surfaces to create the perfect housing for a beautiful gemstone.

Typically, our design team will create the 3-D file using CAD and send the design file to our state-of-the art 3-D printer. Within a few hours, the 3-D print creates a wax model that can be used for casting the piece in precious metal. After the casting process, the “rough” metal piece must be perfected or assembled. Often a piece of jewelry is originally made by multiple smaller parts, so the goldsmith will refine, trim, assemble, and solder the parts together to obtain the final piece. When the goldsmith is finished with his work on the piece, it then moves on to the stone setter who will actually set and secure the stones (more on this below). Sometimes, when a piece is very complex and/or made of multiple parts, the individual parts, after they have been refined and trimmed by the goldsmith, are individually set with the stones before the final piece is fully assembled. Then, of course, the set parts are soldered by the goldsmith to obtain the final piece. Setting the individual parts can allow for a sharper and more precise finished piece.

Stone Setting

Clockwise from upper left – PICCHIOTTI stone setters working with high powered microscopes, PICCHIOTTI Xpandable Sapphire and Diamond cocktail ring, tools and parts used by stone setters, stone setter building a sapphire ring, stone setter hand-setting gemstones into a PICCHIOTTI ring

Once the base of the ring, bracelet, necklace, earrings, or brooch is completed by the goldsmiths, the piece will then be transferred to the stone setting department. Also on the first floor and very near the goldsmiths, we have highly trained artisans who set the impeccable stones in very precise ways. Perfection is key for diamond and gemstone setting, so these craftsmen work with high powered microscopes to finely tune each and every gemstone on a piece of our jewelry. Every gemstone is slightly different, coming from Mother Nature with its own unique properties. Therefore, setting diamonds and gemstones is an incredibly distinctive task. The aim is to set each gemstone so that it has maximum sparkle and delight. The position and the angle of each gem is precisely placed by setters to make the most of the natural beauty of the particular stone they are setting. This is a very delicate task, and every stone must be secured to reduce any risk of the stones falling out. Larger stones must also be securely set to avoid risk of chipping or scratching, as well as risk of loss.

Another very important area on the first floor is the stone selection room. This is where brothers Filippo and Umberto Picchiotti hand select the stones to be set into the various designs. Here, with highly specialized and state-of-the-art lighting, the two brothers evaluate which stones are worthy to be added to our stock, or which ones are not worthy of a PICCHIOTTI piece of jewelry. This is also where the setters go if or when they need to replace certain stones. Additionally, sometimes, the setters may require certain stones to be trimmed, so they will put in their request in this room by talking directly to Filippo or Umberto.

After the stone setting process is complete, the assembled piece goes to the polishers.

Polishing

Clockwise from upper left – model wearing PICCHIOTTI diamond designs from the Xpandable collection, PICCHIOTTI Xpandable tennis bracelet, two images of PICCHIOTTI artisans hand polishing completed diamond designs

A smaller, but equally important, section of the atelier ground floor is dedicated to the polishers. Every diamond, gemstone, and finished piece of PICCHIOTTI jewelry is polished by hand by detail-oriented perfectionists. They precisely clean, polish, and brighten up each stone and each piece of finished jewelry. The polishers have state-of-the-art tools that require particular knowledge to use. The tools include hand-held finely bristled brushes that spin for polishing gold, strings for cleaning in between stones, a spinning wheel with various types of brushes and surfaces, and an ultrasound machine for final polishing of finished jewelry pieces. Some pieces utilize all of these polishing tools at various levels of production. Everything is polished for the brightest shine possible to allow the true natural beauty of the precious metal and the gemstones to be fully appreciated.

The first floor, just above the artisans, are the commercial offices where orders are received, processed, and shipped. The marketing office is also on this floor. The marketing team develops strategies, social media content, television advertising campaigns, including the new digital ad featuring two new videos produced with the most advanced CGI (computer generated imagery) technology available. These videos beautifully showcase the splendor and functionality of the Xpandable™️ and Reversible Xpandable™️ collections. The all-new campaign will launch in early November and run through the holiday season. Stay tuned!

“The PICCHIOTTI atelier is our home away from home,” says Giuseppe Picchiotti. “We spend most of our time living, working, and creating in this space. It is important that the facility itself is as beautiful, clean, and inspirational as the jewelry that we create. We love hosting VIP guests and giving private tours to our best customers. Many of them feel like extended family to us, and we welcome them to our beloved home.”

If you liked this, you might also like:

Italian Jewelry – A Heritage of Craftmanship in Valenza

Vintage Inspired Jewelry Design – Past Meets Present

Designing with Precious Gemstones – How PICCHIOTTI Creates Luxury in Color

The Baguette-Cut Diamond and the Creation of a Signature Style

Feature image at top – from upper left – PICCHIOTTI Il Teatro special edition 50th Anniversary Ruby and Diamond ring, PICCHIOTTI atelier in Valenza, Italy, Giuseppe’s office, historic original door to PICCHIOTTI atelier, Giuseppe Picchiotti